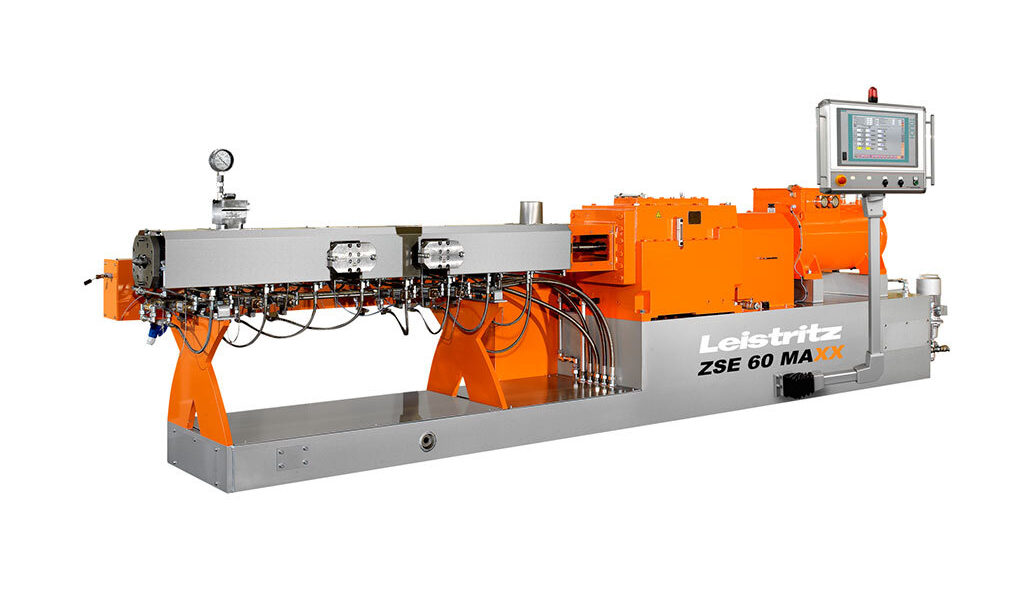

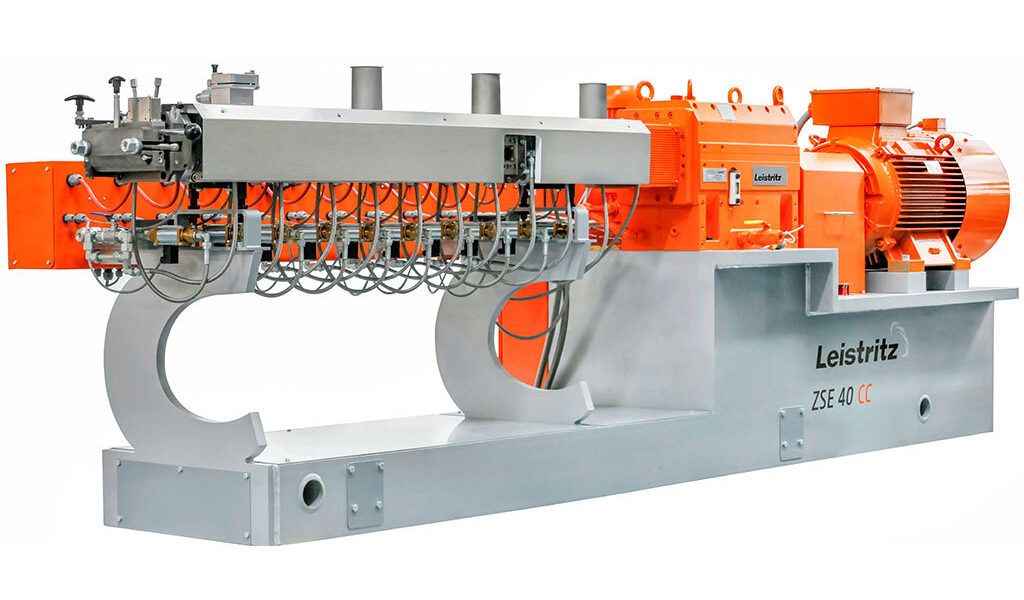

We have established a modern manufacturing facility that helps us in developing our range of color masterbatches, black masterbatches, white masterbatches, additives masterbatches and UV masterbatches and masterbatches for various polypropylene applications like PP non-woven application. Our manufacturing unit is equipped with high installation capacity and the latest technology to allow smooth execution of our production process. We have fully automated plants to serve our clients better according to their desired specifications.

Our manufacturing equipment includes world class extruders, mixers, grinders, dryers and pelletizers. We have extensive knowledge of various polymers like PET, PBT, PPHP, LDPE, LLDPE, Polycarbonate, Nylons, ABS, HIPS, GPPS and PMMA.

Our list of sophisticated R&D equipments include:

LAB FACILITIESS

We are equipped with the most sophisticated lab machinery and equipment for continuous development of innovative products to meet the ever changing needs of our clients.

Some of our sophisticated lab machinery and equipments are as below:

PP Nonwoven Fabric Machine

Spectrophotometer for checking difference in colour values

I.V.(Intrinsic Viscosity) Tester and Melt Flow Index (MFI) Tester

Filter Pressure Value (FPV) Lab Tech Machine

Light Booth for shade matching

Blown Film Line

Lab Scale Extruder lines (Omega 20)

vSheet & Moulding Exhibit Preparation Machines

Injection Moulding machines

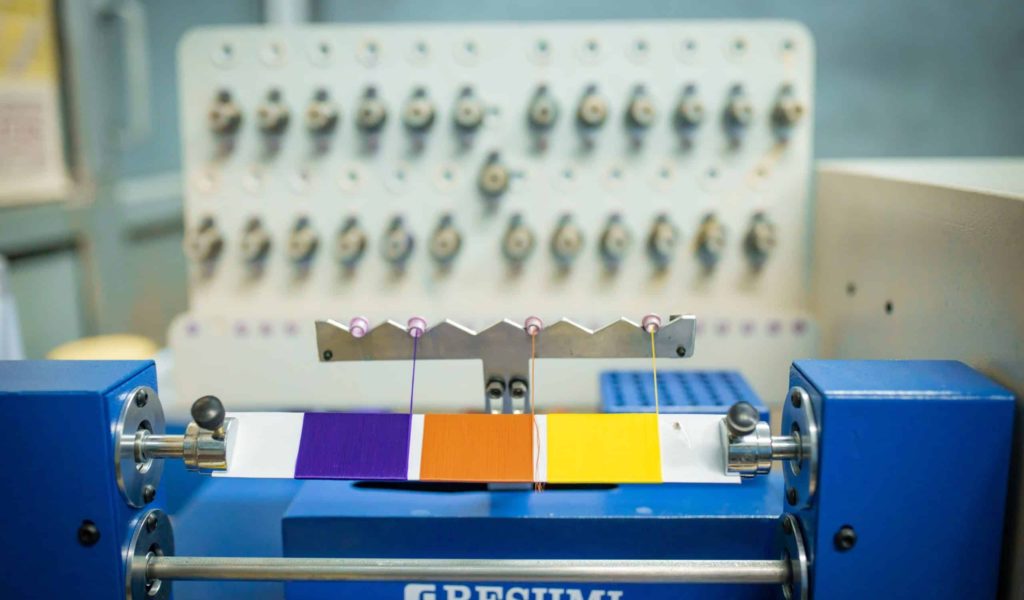

Lab Scale Spinning machine

Lab Scale Machine for Nonwoven Fabric

Lab Scale Film Plant

CBC(Carbon Black Content) Testing

High Speed Mixing Tester

Compression Molding M/c

Moisture Analyzer

Hot Air Oven

Muffle Furnace

Pantone and RAL shade cards

Filler Content Analysis

MACHINERY IMAGES

MACHINERY IMAGES

DOWNLOAD A COMPLETE CATALOG OF OUR PRODUCT OFFERINGS